The food industry is increasingly moving toward new product development and innovative propositions through new processing methods that allow doing things you could not do before.

One of the most successful developments made to date is High Pressure Processing (HPP).

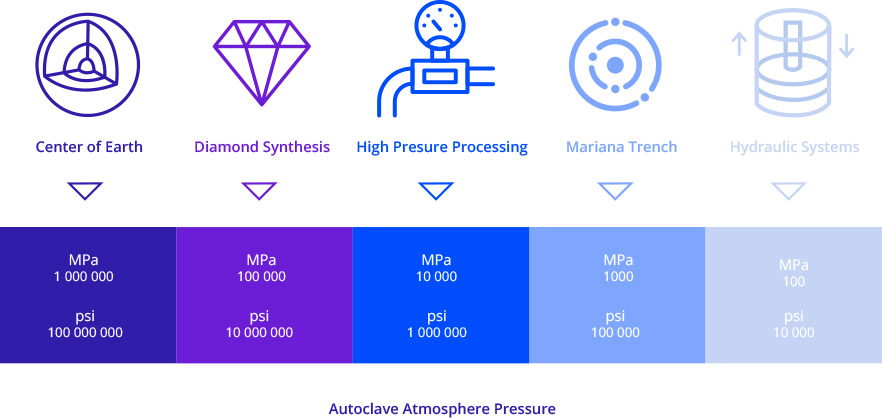

High Pressure Processing (HPP) is an FDA approved method of treating foods and juices to dramatically reduce or eliminate harmful bacteria and extend the shelf life. This is done with a cold pasteurization technique. By which products, already sealed in their final packages, are introduced into a vessel and subjected to a high level of hydrostatic pressure (pressure transmitted by water) up to 600 MPa / 87,000 psi for a few seconds to a few minutes. It is the same effect as subjecting the food to an ocean depth of 60 Km deep -if an ocean this deep existed. Extending shelf life anywhere from 45-90 days.

High Pressure Processing is a natural, environmentally friendly process that respect's the ingredients and helps maintain the fresh food characteristics, like flavor and nutrients. It is a real alternative to traditional thermal and chemical treatments.

High Pressure Processing (HPP) is a cold pasteurization technique by which products, already sealed in its final package, are introduced into a vessel and subjected to a high level of isostatic pressure (300–600MPa/43,500-87,000psi) transmitted by water.Pressures above 400 MPa / 58,000 psi at cold (+ 4ºC to 10ºC) or ambient temperature inactivate the vegetative flora (bacteria, virus, yeasts, moulds and parasites) present in food, extending the products shelf life importantly and guaranteeing food safety. High Pressure Processing respects the sensorial and nutritional properties of food, because of the absence of heat treatment, and maintains its original freshness throughout the shelf-life.

To meet the demands of the 21st century consumer (convenience foods, higher sensorial and nutritional quality, additive free/natural, functional products, etc.), food companies need to innovate by using the latest non-thermal technologies, and High Pressure Processing is the most relevant one.

Thermal methods, traditionally used in the food industry for food preservation, carry disadvantages like vitamin destruction or flavour changes that can be avoided with HPP.

SOURCE: WWW.HIPERBARIC.COM